I am somewhat new to this site, so don't punish me for asking stupid questions. I previously had a 2013 Sport, and if I remember right, it had some kind of 4WD function? I now have new generation 2019 RTL, and wondered what if any difference there is with this truck only being AWD mode. I live in the midwest and we are currently getting hammered with snow. So far so good as far as getting around in this truck. I really like it, and I have yet to use the snow mode. Just looking for some comparison to what the old generation had compared to my 2019. Thanks in advance.

bretmc

AWD vs. 4WD

1 reading

bretmc

Discussion starter

24 posts

·

Joined 2013

- Add to quote Only show this user

I am somewhat new to this site, so don't punish me for asking stupid questions. I previously had a 2013 Sport, and if I remember right, it had some kind of 4WD function? I now have new generation 2019 RTL, and wondered what if any difference there is with this truck only being AWD mode. I live in the midwest and we are currently getting hammered with snow. So far so good as far as getting around in this truck. I really like it, and I have yet to use the snow mode. Just looking for some comparison to what the old generation had compared to my 2019. Thanks in advance.

24,892 posts

·

Joined 2005

Same, only different. G1 RL had VTM-4. G2 RL has iVTM-4 system.. a bit more refined than the G1 system and offers torque vectoring whereas the G1 RL just had power shift front to rear as needed without torque vectoring.

1,413 posts

·

Joined 2018

In a parking lot a couple of nights ago with no cars near me and I stopped the vehicle. Punched the throttle to the floor and the wheels hardly lost traction while it accelerated much faster than I thought it would. The AWD system on the G2 works quite well.

31,951 posts

·

Joined 2007

The terms 4WD and AWD are often used interchangeably and confusingly.

Customarily, 4WD refers to a part-time system that uses a center differential. There are variations that have locking front, rear, and/or center differentials. Honda does not have a system like this. 4WD systems can't be used on dry pavement. These are heavy-duty systems.

AWD refers to a full-time system that may or may not use a center differential. There are many variations of AWD systems as well.

There are four main differences between the VTM-4 AWD system in the 2006-2014 Ridgeline and the iVTM-4 AWD system used in the 2017-current Ridgline:

1. iVTM-4 has a higher rear overdrive ratio (2.7% vs. 0.8%). This gives a better torque vectoring effect.

2. iVTM-4 has torque vectoring (can transfer power from side-to-side in addition from front-to-rear). This send more torque to the outside rear wheel to push the vehicle through turns and help create a yaw moment.

3. The iVTM-4 clutches are hydraulically actuated whereas the the VTM-4 clutches were electomagnetically actuated.

4. The iVTM-4 system requires Dual Pump Fluid II instead of VTM-4 Fluid.

Customarily, 4WD refers to a part-time system that uses a center differential. There are variations that have locking front, rear, and/or center differentials. Honda does not have a system like this. 4WD systems can't be used on dry pavement. These are heavy-duty systems.

AWD refers to a full-time system that may or may not use a center differential. There are many variations of AWD systems as well.

There are four main differences between the VTM-4 AWD system in the 2006-2014 Ridgeline and the iVTM-4 AWD system used in the 2017-current Ridgline:

1. iVTM-4 has a higher rear overdrive ratio (2.7% vs. 0.8%). This gives a better torque vectoring effect.

2. iVTM-4 has torque vectoring (can transfer power from side-to-side in addition from front-to-rear). This send more torque to the outside rear wheel to push the vehicle through turns and help create a yaw moment.

3. The iVTM-4 clutches are hydraulically actuated whereas the the VTM-4 clutches were electomagnetically actuated.

4. The iVTM-4 system requires Dual Pump Fluid II instead of VTM-4 Fluid.

That video is full of misleading and incorrect information that I'd love to pick apart when I have time. For now, I'll point that the VTM-4 AWD system used in the Pilot and Ridgeline is a reactive and proactive (he says it's reactive only) system while the Real Time AWD system used in the CR-V is reactive only (he says it's proactive, but the CR-V didn't gain proactive capability until the 2017 year model). This video was published in 2013 before iVTM-4 and the updated system used in the 2017-current CR-V.

563 posts

·

Joined 2018

Improved design & advance clutch materials allow iVTM4 to operate at high speeds.

Due heat & wear of clutch AWD is never sending power to all 4 wheels all the time. The front wheel is powered all the time with a minimum of 30%. Up to 70% of engine power can be sent to the rear wheels. All 70% can go to the outside rear wheel wheel during a turn to provide up to 2.7% overdrive - aka torque vectoring. This helps correct understeering issues.

The 4 modes of iVTM4 alters drive by wire (throttle mapping), shift mapping, awd rear bias, awd torque vectoring & vehicle stability control to help get you unstuck. Mud mode allows for some wheel slippage & sand more allows for more wheel slippage. You can also turn off vsa.

Hope all that helps. Stay safe out there.

Due heat & wear of clutch AWD is never sending power to all 4 wheels all the time. The front wheel is powered all the time with a minimum of 30%. Up to 70% of engine power can be sent to the rear wheels. All 70% can go to the outside rear wheel wheel during a turn to provide up to 2.7% overdrive - aka torque vectoring. This helps correct understeering issues.

The 4 modes of iVTM4 alters drive by wire (throttle mapping), shift mapping, awd rear bias, awd torque vectoring & vehicle stability control to help get you unstuck. Mud mode allows for some wheel slippage & sand more allows for more wheel slippage. You can also turn off vsa.

Hope all that helps. Stay safe out there.

Attachments

-

201.2 KB Views: 1,401

60 posts

·

Joined 2018

So hypothetically, if someone were going to drag race the Ridgeline it would be best to put it in mud mode?

2,779 posts

·

Joined 2013

520 posts

·

Joined 2016

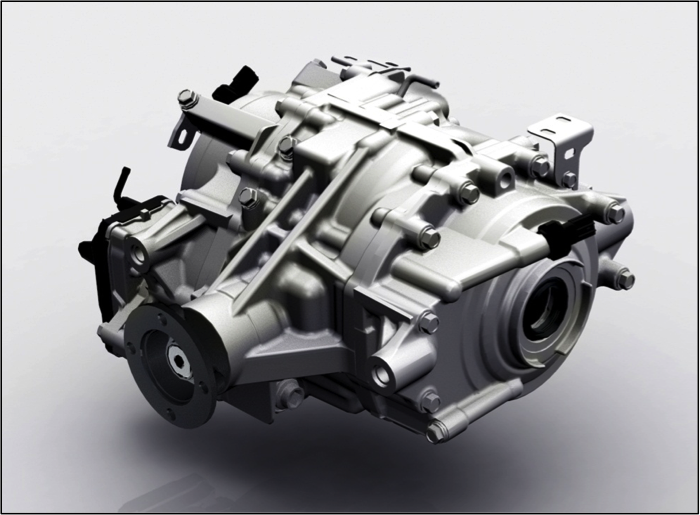

I think the "evidence" of the iVTM-4 system being bigger and bulkier than the original VTM-4 is the decrease in size of the in bed trunk in the G2 Ridgeline. :wink:Also, the new iVTM-4 is 22% lighter and can handle 20% more torque than the original VTM-4 from the first generation Ridgeline (Gen1). Physically, I think the iVTM-4 is also bigger and bulkier than the original VTM-4 but I cannot prove that.

VTM-4

View attachment 384124

iVTM-4

![Image]()

That said, I love how it performs.

24,892 posts

·

Joined 2005

Quick question on the ivtm-4 system... is it also subject to the silent failure condition like the original vtm-4 system?

31,951 posts

·

Joined 2007

Yes. There are no speed or torque sensors for feedback, so the system has no idea how much torque is actually being transferred to each rear wheel. All it knows is how much torque is being commanded to each rear wheel. The only sensors the iVTM-4 system has are a fluid temperature sensor and oil pressure sensors. The oil pressure sensors can help determine if the motor, pump, or solenoid valves aren't working and are used to infer the amount of torque being transferred to each wheel based on the assumption that each clutch can still hold an specified amount of toque based on the hydraulic pressure being applied.

For what it's worth, "silent failures" can occur in any AWD system - not just Honda's. In order to detect a silent failure, you'd need torque sensors on each wheel that can be used to compare the measured torque with the commanded torque. I'm not aware of any AWD system that uses torque sensors. Normally, you'll notice a noise or detect a change in handling or a decrease in traction.

The "wheel power" displays found in the CR-V, Pilot, and RDX are displaying the commanded torque to each wheel - not the measured torque. If you physically removed the propeller shaft from any of these vehicles, the display would still show power being sent to the rear wheels and there would be no warning lights at all.

For what it's worth, "silent failures" can occur in any AWD system - not just Honda's. In order to detect a silent failure, you'd need torque sensors on each wheel that can be used to compare the measured torque with the commanded torque. I'm not aware of any AWD system that uses torque sensors. Normally, you'll notice a noise or detect a change in handling or a decrease in traction.

The "wheel power" displays found in the CR-V, Pilot, and RDX are displaying the commanded torque to each wheel - not the measured torque. If you physically removed the propeller shaft from any of these vehicles, the display would still show power being sent to the rear wheels and there would be no warning lights at all.

1,245 posts

·

Joined 2017

And I believe your old RL had a selector to lock the rear in for severe conditions up to 20mph whereas the new RL is all automatic.

563 posts

·

Joined 2018

th documentation I saw was full70% up to 6mph, the linearly ramped down to 0% at 18mph.

6,084 posts

·

Joined 2005

With all due respect . . .I think that Joe (Cismo) coined the GenI VTM4 "silent failure" term. In all my years here I have never seen any evidence that such failures are common or even uncommon.

Its true that one might say that that is exactly the point with a silent failure . . . No one reports it because you can't easily tell its happened. . . .

To that I would say . . .Take your rear driveshaft off of your Ridgeline and drive it aggressively for 5 minutes. It will become quickly apparent how much the rear wheels are doing in everyday driving. Basically a failure won't be silent at all but rather pretty darn obvious.

Bottom line . . .IMHO GenI VTM4 "silent failures" are rare if non existent with no proper supporting evidence ever provided.

Its true that one might say that that is exactly the point with a silent failure . . . No one reports it because you can't easily tell its happened. . . .

To that I would say . . .Take your rear driveshaft off of your Ridgeline and drive it aggressively for 5 minutes. It will become quickly apparent how much the rear wheels are doing in everyday driving. Basically a failure won't be silent at all but rather pretty darn obvious.

Bottom line . . .IMHO GenI VTM4 "silent failures" are rare if non existent with no proper supporting evidence ever provided.

24,892 posts

·

Joined 2005

I kinda think the same as you on this. If the VTM-4 has silently failed, I'm thinking hard acceleration from a stop would show up as some front tire slip/squeal, just as one testing measure. Else the traction control system will cut power to minimize wheel spin.

153 posts

·

Joined 2018

I have owned both AWD and 4wd ......... without getting into more of the engineering of them ... the the main thing that differentiates them is

awd ...... all wheels are turning under power

4wd is when you call for it, either by a button or locking hubs and moving a lever (like older models)

all-wheel drive system can send a variable amount of torque to each axle, and the driver doesn't typically control this. Most all-wheel drive system uses a center differential to distribute the engine's torque between the two axles

A four-wheel drive system sends a fixed amount of power to each axle, and it can be switched on or off by the driver. It relies on a transfer case, which functions like a locked differential

Since 2017-2018 most 4wd vehicles have some modification that makes them not pure 4wd as described above. GMC/Chevy Ford and Toyota all have some kind of hybrid awd aspect to their 4wd systems now

What's better ? really unless you are hard core 4-wheeler awd will do better inmost conditions........ Mostly because- the computer and be more adaptive and react and learn to adapt its program to be proactive .... just as ZRoger73 very nicely outlined.

That video Zroger73 commented on is way too outdated to be relevant. As for silent failure aspects and monitoring really ???..... 99% of life does not get that level of review.......... just sayin .... The Honda awd that is the latest and greatest and performs as good as virtually all other makers and then some...... my 2¢

awd ...... all wheels are turning under power

4wd is when you call for it, either by a button or locking hubs and moving a lever (like older models)

all-wheel drive system can send a variable amount of torque to each axle, and the driver doesn't typically control this. Most all-wheel drive system uses a center differential to distribute the engine's torque between the two axles

A four-wheel drive system sends a fixed amount of power to each axle, and it can be switched on or off by the driver. It relies on a transfer case, which functions like a locked differential

Since 2017-2018 most 4wd vehicles have some modification that makes them not pure 4wd as described above. GMC/Chevy Ford and Toyota all have some kind of hybrid awd aspect to their 4wd systems now

What's better ? really unless you are hard core 4-wheeler awd will do better inmost conditions........ Mostly because- the computer and be more adaptive and react and learn to adapt its program to be proactive .... just as ZRoger73 very nicely outlined.

That video Zroger73 commented on is way too outdated to be relevant. As for silent failure aspects and monitoring really ???..... 99% of life does not get that level of review.......... just sayin .... The Honda awd that is the latest and greatest and performs as good as virtually all other makers and then some...... my 2¢

This post has been deleted

563 posts

·

Joined 2018

If we can find the diff temp pid we can extrapolate temp increase as a sign of power being delivered.

413 posts

·

Joined 2018

Here's another video demonstrating the SH-AWD on an RDX and the iVTM-4 on Pilot, which is what's used on the Ridgeline as well:

413 posts

·

Joined 2018

You're very welcome. I stumbled across it last night, which was a happy accident.

24,892 posts

·

Joined 2005

Technically, conventional 4wd vehicles without lockers only get power to 2 wheels, one wheel per axle is powered since it has open diffs, front and rear. With an AWD system like the VTM-4 system, only 3 wheels get powered because the front wheels are driven by an open differential while the rear wheels are both driven at the same time by electromag clutches in the rear diff.

VSA makes the front wheels act kinda like they're driven by a limited slip differential by using braking of the spinning wheel to transfer power to the non-spinning wheel, but if left unmodulated (switch off VSA), the wheel with less traction will sit there and spin while the wheel with traction does nothing.

Of course the rear wheels in a VTM-4 system are both driven at the same time via the electromag clutches in the rear diff. I understand the iVTM-4 system uses hydraulics to enable torque vectoring. I am otherwise unfamilar with iVTM-4.

I suspect the G2 RL has a similar open diff in the front and is also a 3-wheel drive vehicle, but enjoys superior performance due to having the ability to direct power side-to-side as well as front to rear. (torque vectoring).

Inasmuch as a conventional mechanical 4wd vehicle (without lockers) is still called 4wd (even though only 1 wheel per axle is powered), Honda can still call their 3wheel drive vehicles 4wd. I suppose AWD is somewhat more of an adaption of the older 4wd terminology given that an AWD vehicle typically directs power where needed and doesn't have on/off pavement restrictions like conventional mechanical 4wd vehicles with 4Hi/4Lo which should never be operated on dry pavement with 4wd engaged.

VSA makes the front wheels act kinda like they're driven by a limited slip differential by using braking of the spinning wheel to transfer power to the non-spinning wheel, but if left unmodulated (switch off VSA), the wheel with less traction will sit there and spin while the wheel with traction does nothing.

Of course the rear wheels in a VTM-4 system are both driven at the same time via the electromag clutches in the rear diff. I understand the iVTM-4 system uses hydraulics to enable torque vectoring. I am otherwise unfamilar with iVTM-4.

I suspect the G2 RL has a similar open diff in the front and is also a 3-wheel drive vehicle, but enjoys superior performance due to having the ability to direct power side-to-side as well as front to rear. (torque vectoring).

Inasmuch as a conventional mechanical 4wd vehicle (without lockers) is still called 4wd (even though only 1 wheel per axle is powered), Honda can still call their 3wheel drive vehicles 4wd. I suppose AWD is somewhat more of an adaption of the older 4wd terminology given that an AWD vehicle typically directs power where needed and doesn't have on/off pavement restrictions like conventional mechanical 4wd vehicles with 4Hi/4Lo which should never be operated on dry pavement with 4wd engaged.

24,892 posts

·

Joined 2005

One aspect of the power transfer (up to 70%) I've never understood is exactly how is that percentage accomplished? What mechanism works to limit the power to 70%? Is it a design clutch limitation/slippage such that power above 70% results in automatic clutch slippage?

I've never found an explanation that made sense to me.

I've never found an explanation that made sense to me.

31,951 posts

·

Joined 2007

Yes.What mechanism works to limit the power to 70%? Is it a design clutch limitation/slippage such that power above 70% results in automatic clutch slippage?

Let's look at the G2 as an example.

The engine develops a maximum of 262 lb-ft of torque.

First gear has a ratio of 3.359:1. That gives us 880 lb-ft of torque at the transmission's output shaft.

The final drive ratio is 4.25:1. That gives us 3,740 lb-ft of torque to the front axle.

The iVTM-4 unit has a mechanical overdrive of 2.7%. That gives us 3,642 lb-ft of torque to the rear clutches.

NOTE: Actual torque values will be lower due to mechanical losses, but are not important for this discussion.

If "up to 70% of total available torque can be sent to the rear wheels", one or more of the following explanations can be implied:

1) The clutches are physically unable to hold more than 2,549 lb-ft (70% of 3,642 lb-ft) of torque before they begin slipping due to the surface area, coefficient of friction, and clamping force being applied. This is the most likely answer in my opinion.

2) It may be unnecessary and potentially negative to transfer more than 70% of available torque to the rear wheels since they have less grip than the front wheels due to the weight distribution (~60/40) and because it may result in oversteer due to the 2.7% overdrive. This is possible.

3) The iVTM-4 system is capable of holding all available torque, but with a 2.7% overdrive, windup would occur very quickly causing the vehicle to bog down on dry pavement and/or lose traction due to slipping wheels so the system avoids a "100% complete mechanical lock". This is possible as well.

4) The clutches are physically able to hold more than 2,549 lb-ft, but other components of the iVTM-4 system such as gears, bearings, axles, and/or the case itself aren't so the system limits clamping force being applied to the clutches so that they won't allow more than 70% of available torque to be transmitted. This is unlikely.

5) The hydraulic system is incapable of developing enough pressure to apply the clamping force necessary for the clutches to handle more than 2,549 lb-ft of torque without slipping. This is also unlikely.

563 posts

·

Joined 2018

I'm still trying to wrap my head around the iVTM4 system. Here is an excerpt from honda.System Layout

The Ridgeline AWD system is a fulltime system that requires no driver interaction or monitoring, thanks to a torque-transfer unit that is bolted directly to the front-mounted transaxle. The torque-transfer unit receives torque from a helical gear that is attached to the front differential's ring gear, and a short horizontal shaft and hypoid gear set within the torque-transfer unit's case send power to the rear propeller shaft....

@zroger73 from the materials I read, the front wheels operation range is 30-100% of torque. That would mean the rear differential/clutch only sees 70% of engine power.

31,951 posts

·

Joined 2007

I'm still trying to wrap my head around the iVTM4 system. Here is an excerpt from honda.

@zroger73 from the materials I read, the front wheels operation range is 30-100% of torque. That would mean the rear differential/clutch only sees 70% of engine power.

(i)VTM-4 is an add-on system. Fundamentally, the vehicle is front-wheel drive. On AWD models, there is what is essentially a PTO (Power Take-Off) on the output shaft of the transmission (the same output shaft that turns the front differential carrier) that turns the propeller shaft and pinion and ring gears inside the (i)VTM-4 unit whenever the front wheels are rotating. There are two, variable-capacity clutches in the (i)VTM-4 unit - one on each side between each ring gear and driven wheel. The (i)VTM-4 unit's ring gear rotates 2.7% faster than the front axle at all times. The system varies the amount of clamping force to each clutch by various amounts under various conditions to apply various amounts of torque to each rear wheel.That's all good and well, but shouldn't we use sixth gear when calculating max torque throughput, since the key phrase is "up to70%"? Maybe in first gear, it will only deliver up to 17% max torque to the rear axle.

However, that seems a bit unlikely, so maybe the 70% is an artificial limitation for reasons alluded to in your points 2 and 3?

Despite what some say or believe, there is NO mechanism that proportions power to the front and rear axles independently. The front axle is always capable of receiving 100% of the torque produced by the engine regardless of the degree to which the rear clutches are applied.

Example: If the front wheels are on dry pavement and the rear wheels are on a solid sheet of ice and you floor the accelerator, the system will proactively and fully apply the rear clutches so that the rear wheels receive as much of the available torque as possible, BUT THE REAR CANNOT "STEAL" TORQUE FROM THE FRONT WHEELS. Even with the clutches fully applied, there is virtually no torque being transmitted to the rear wheels because they are free to spin with no resistance. In this scenario the vehicle will accelerate as if it were front wheel drive only.

24,892 posts

·

Joined 2005

Interesting. So it sounds like there is constant wear and tear going on due to clutch slippage in daily driving. Wonder what the design life of the clutches is for the (i)VTM-4 system? Sounds like a good reason to maintain rear diff fluid changes and illustrates the difference between conventional pumpkins and the AWD function of the (i)VTM-4 system. I don't recall ever changing the fluid in a conventional pumpkin (rear diff).

31,951 posts

·

Joined 2007

An open differential or a Torsen/helical limited slip differential has nothing in it but gears. There are no clutches, no electromagnets, no solenoids, no hydraulic pumps, no temperature sensors, and no pressure sensors. All the fluid needs to do is lubricate the gears to prevent metal-to-metal contact.

The (i)VTM-4 has no differential gear assembly to allow the rear wheels to rotate at different speeds. Instead, it allows independent wheels speeds via clutch slip. The fluid not only has to lubricate the moving parts, but it also has to transfer heat from the clutch packs and serve as hydraulic fluid to apply pressure to the pistons that compress the clutch plates.

Yes, there's always clutch slip occurring even when driving in a straight line because of the 2.7% overdrive. However, the amount of friction, heat, and wear resulting from this slip varies depending on how much force is being applied to the clutches through the hydraulic pump, solenoid valves, and pistons - very little at cruising speeds without a load to a lot when you're pulling a 5,000 lb. boat and trailer up a steep ramp at 5 MPH.

Torque only occurs when there is a load. If you floor the accelerator with all four wheels on ice, there's very little torque occurring anywhere because there's very little friction (load) between the tires and the ice. If you floor the accelerator with all four wheels on dry pavement, either the tires or the clutches must slip. In this case, the clutches lose.

Think about it this way - if you're using a torque wrench to rotate a loose bolt that rotates freely with almost no resistance, there's almost no torque being transferred. As that bolt begins to tighten, more torque is required to rotate it. The speed at which you rotate it and the amount of force required to turn it becomes horsepower. Once you reach the desired torque, the torque wrench clicks and you know to stop. If you keep applying even more force, you'll eventually strip the threads, shear the bolt, or round off the threads.

The (i)VTM-4 has no differential gear assembly to allow the rear wheels to rotate at different speeds. Instead, it allows independent wheels speeds via clutch slip. The fluid not only has to lubricate the moving parts, but it also has to transfer heat from the clutch packs and serve as hydraulic fluid to apply pressure to the pistons that compress the clutch plates.

Yes, there's always clutch slip occurring even when driving in a straight line because of the 2.7% overdrive. However, the amount of friction, heat, and wear resulting from this slip varies depending on how much force is being applied to the clutches through the hydraulic pump, solenoid valves, and pistons - very little at cruising speeds without a load to a lot when you're pulling a 5,000 lb. boat and trailer up a steep ramp at 5 MPH.

The front wheels are permanently connected to the transmission. Unlike in the rear, nothing exists to disconnect or limit the torque being applied to them.For further clarification, does the FWD unit always receive 100% of the engine's output torque? Or are there some situations where the FWD receives, say, 70% of the torque while the RWD portion also receives, say, 50% of the engine's torque output?

Torque only occurs when there is a load. If you floor the accelerator with all four wheels on ice, there's very little torque occurring anywhere because there's very little friction (load) between the tires and the ice. If you floor the accelerator with all four wheels on dry pavement, either the tires or the clutches must slip. In this case, the clutches lose.

Think about it this way - if you're using a torque wrench to rotate a loose bolt that rotates freely with almost no resistance, there's almost no torque being transferred. As that bolt begins to tighten, more torque is required to rotate it. The speed at which you rotate it and the amount of force required to turn it becomes horsepower. Once you reach the desired torque, the torque wrench clicks and you know to stop. If you keep applying even more force, you'll eventually strip the threads, shear the bolt, or round off the threads.

2,779 posts

·

Joined 2013

Although this is about the older VTM-4 system, this disassembly report is interesting nonetheless: Honda/Acura VTM-4

31,951 posts

·

Joined 2007

Not sure how I missed this (especially considering that I owned a 2019 RDX) but a 4th-generation SH-AWD system was introduced on this model that offers 30% faster response and 40% more torque capacity than the 3rd-generation SH-AWD system to which the current Ridgeline's iVTM-4 system is most similar.

I learned this today after Honda published a brief history of SH-AWD on its 15th anniversary.

I learned this today after Honda published a brief history of SH-AWD on its 15th anniversary.

Attachments

-

54.5 KB Views: 271

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 1.4M

- members

- 98K

- Since

- 2004

Honda Ridgeline Owners Club, forum community to discuss reviews, accessories, performance, care, mods, and more.